Advantages of the machine:

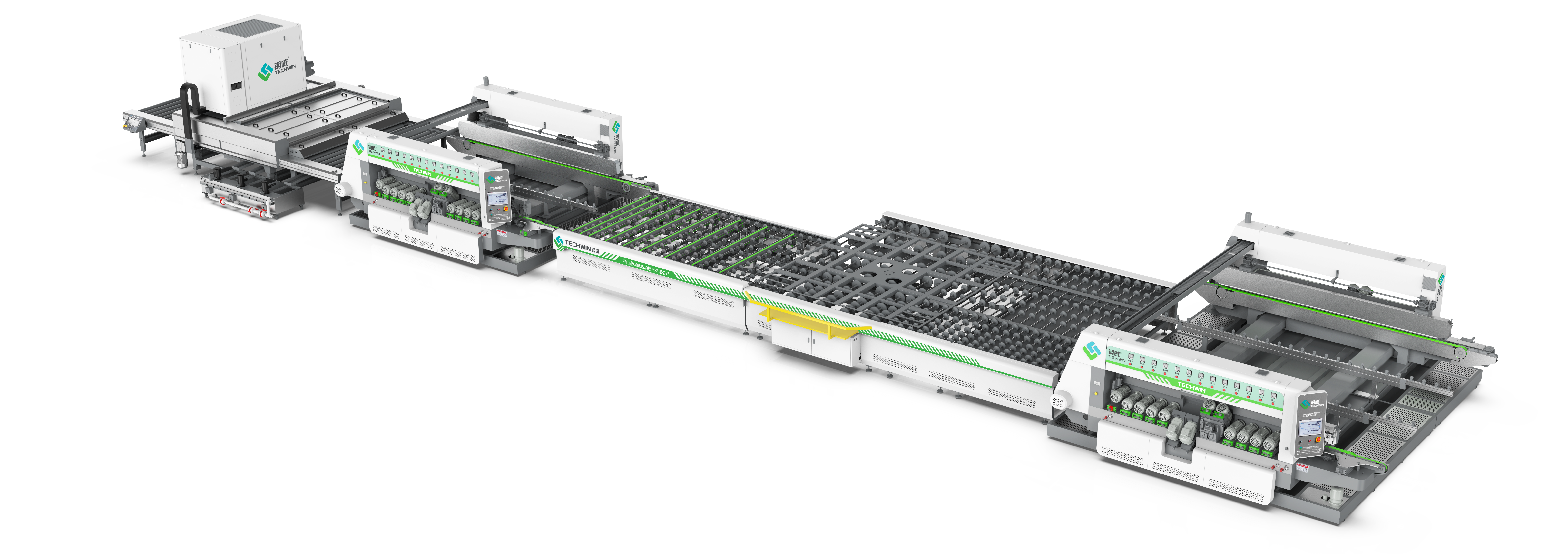

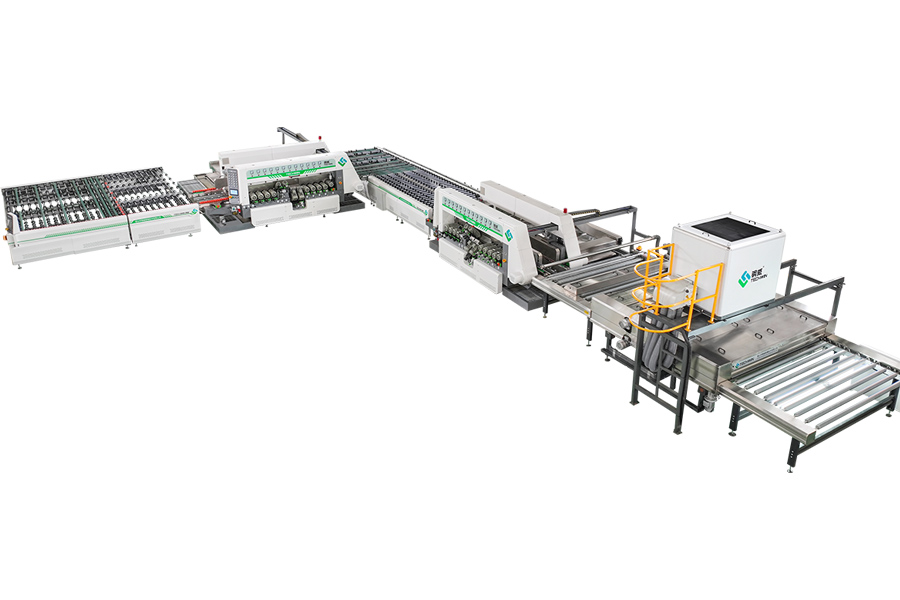

Techwin offers a wide ranges of glass double edgers in different sizes and speeds, they can used for processing shower glass, home appliance glass, furniture glass, shower glass, architectural glass and aquamarine glass. A double edging line includes an automatic measuring table, two double edgers and a turning conveyor. Techwin offers 18 spindles in one edger for high speed processing, 22-26 spindles for high speed grinding and fine polishing. Besides, corner dubbing controlled by servo and Low-E removal are as options. Techwin double edger is also capable to process laminated glass.

| TECHNICAL PARAMETERS | TWMT-1200 | TWMT-2500 | TWMT-3600 | TWMT-4500 | TWMT-5000 |

|---|---|---|---|---|---|

| Motor quantity | 20-26 | 20-26 | 20-26 | 20-26 | 20-26 |

| Maximum glass width | 1200 mm | 2500 mm | 3600 mm | 4500 mm | 5000 mm |

| Minimum glass size | 350×350 mm | 350×350 mm | 350×350 mm | 550×550 mm | 550×550 mm |

| Glass thickness | 3-25 mm | 3-25 mm | 3-25 mm | 3-25 mm | 3-25 mm |

| Glass processing speed | 6 - 20 m/min | 6 - 20 m/min | 6 - 20 m/min | 6 - 20 m/min | 6 - 20 m/min |

| Size changing speed | 1-15 m/min | 1-15 m/min | 1-15 m/min | 1-15 m/min | 1-15 m/min |

| Diagonal tolerance of glass processing | ± 0.5 mm/m | ± 0.5 mm/m | ± 0.5 mm/m | ± 0.5 mm/m | ± 0.5 mm/m |

| Parallel tolerance of glass processing | ± 0.1 mm/m | ± 0.1 mm/m | ± 0.1 mm/m | ± 0.1 mm/m | ± 0.1 mm/m |

| Flat edge cutting amount/sigle side | 1-4mm | 1-4mm | 1-4mm | 1-4mm | 1-4mm |

Glass double edging machines provided by Techwin are among the top level in China.

Backed by a team of technicians with 30+ years of experience on double edgers, and production experts who had real glass processing experience, we ensure every machine is built with attention to detail and technical excellence.

Heavy-Duty Welded Frame: Built from thick steel beams to ensure long-term rigidity and vibration-free grinding.

CNC Machined Base: Ensures parallel alignment of guide rails and consistent glass positioning.

Powder Coated and Rust-Proof Paint Finish: Increases durability and corrosion resistance in wet environments.

With measuring table, glass width and length can be measured automatically and the information will sent to the other machines in the line. The double edgers can adjust the width and thickness automatically, and the washing machine can be synchronous in speed and thickness.

Memory function for storing multiple glass sizes and processing parameters for quick recall and production changeover. Speed for different thickness is pre set, and it will change to the proper speed when thickness changes.

Touchscreen HMI Interface with multi-language support.

Equipped with high-speed rotation motors for rough grinding to ensure high torque and low vibration at all RPM levels.

Precise zero point positioning for each grinding wheels to make sure accurate control of cutting amount.

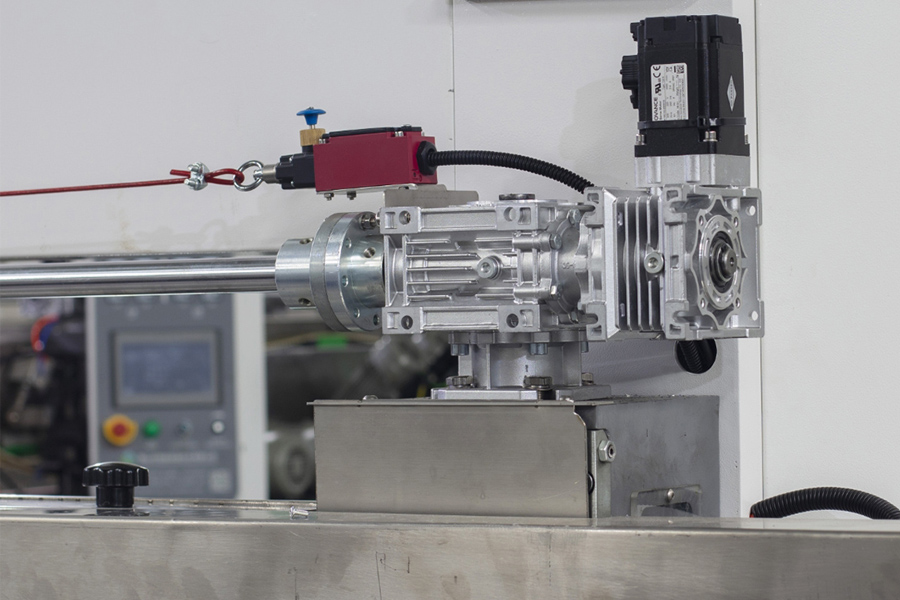

Three options for grinding wheels control: servo motors for all grinding wheels; servo motor for rough grinding and cylinder for polishing; manual adjustment on rough grinding and cylinders for fine polishing.

Modular Machine Layout: Quick access to electrical box, lifting gears, spindles, and belts.

Electrical Lubrication System: Electrical lubrication for ball bearings and motor bases.

Grinding wheel replacement: Machine pressing system can lift up max. 150mm for easy wheel replacement.

Full Machine Covers : All the transmission gears or chains are protected to avoid injuries.

Emergency Stop Buttons: Easily accessible on multiple sides of the machine.

Over Size Protection: When thick glass size is not properly cut, the glass size will not match the input parameters, the machine will detect and slow down the speed to avoid damaging the grinding wheels.

Automatic glass loading and unloading machines.

Bar code reading systems.

Low-e removal wheels.

Servo system for corner dubbing.

Glass turning conveyor for L shape, I shape or U shape lines.

Integrate with cutting or washing machines.