Introducing Our Advanced Glass Pencil Double Edging Line: Precision, Efficiency, and Innovation

In the world of glass processing, precision, efficiency, and reliability are paramount. TECHWIN’s Glass Pencil Double Edging Line stands out as a state-of-the-art solution designed to meet the demanding needs of modern glass fabrication. This line is engineered to deliver exceptional performance, making it ideal for processing furniture glass, home appliance glass, and solar glass. Let’s dive deeper into the features, benefits, and technical advantages of this cutting-edge system.

Overview of the Glass Pencil Double Edging Line

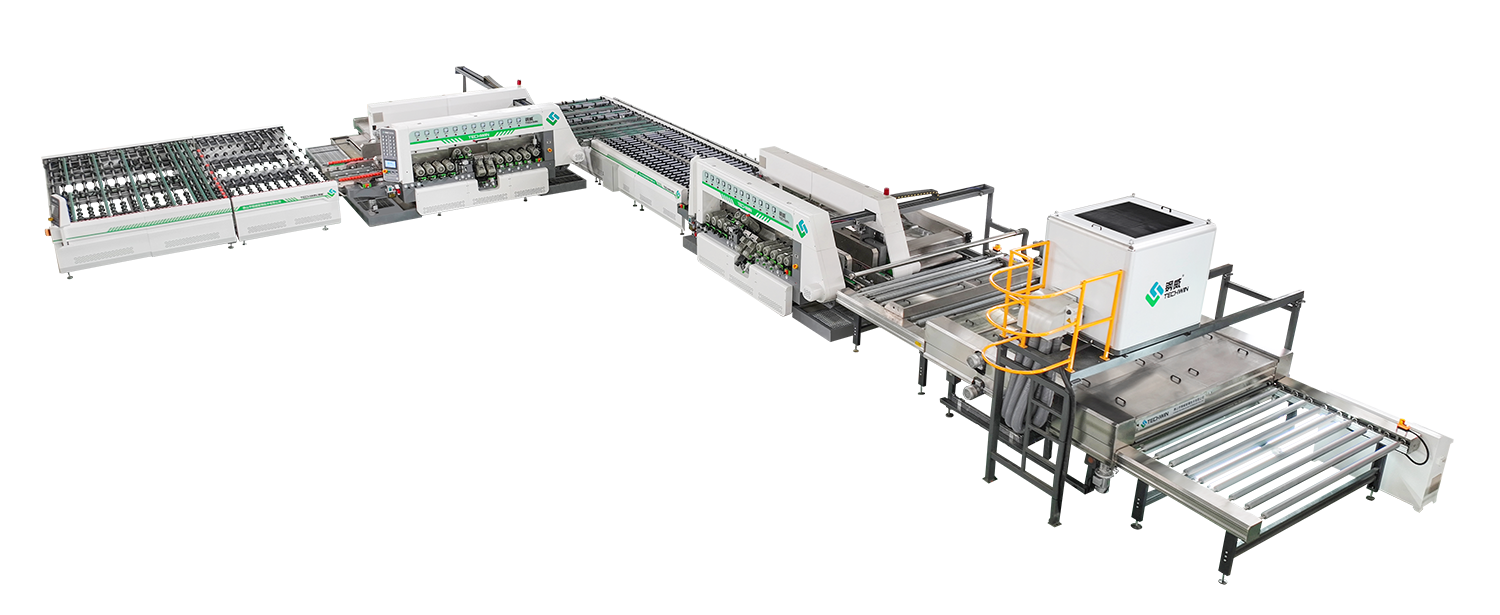

Our double edging line is a comprehensive system that includes:

- First Double Edger: Equipped with 8-16 grinding motors for rough or fine polishing.

- Straight Turning Table: Ensures smooth and precise glass transfer between edgers.

- Second Double Edger: Completes the finishing process with high precision.

This integrated line is designed to handle a wide range of glass thicknesses and sizes, delivering consistent results for both straight and pencil-edge glass processing.

Key Features and Innovations

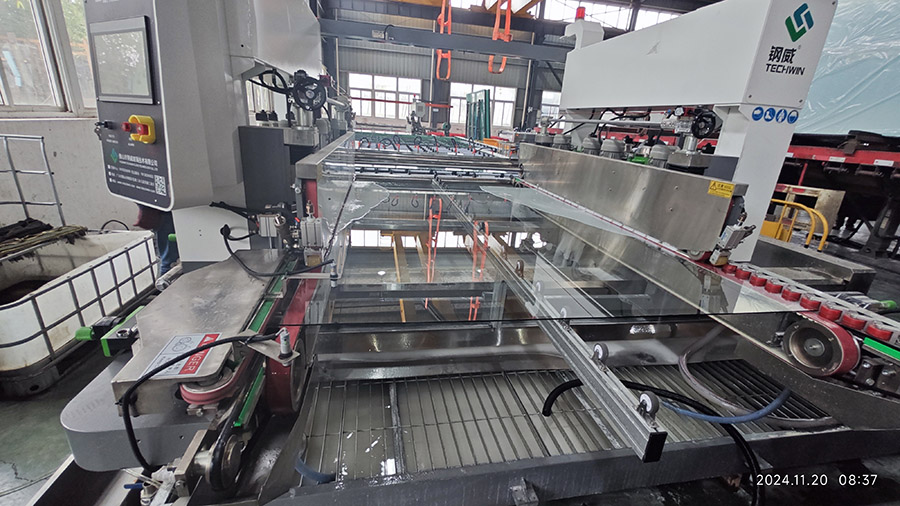

- 180-Degree Rotating Grinding Wheels

One of the standout features of our double edger is the ability of the grinding wheels to rotate 180 degrees outward. This innovative design allows for quick and easy replacement of grinding wheels without interrupting production. Compared to traditional machines, this feature significantly reduces downtime and enhances operational efficiency. - High-Capacity Grinding Motors

Each edger is equipped with 8-16 grinding motors, ensuring versatility in processing. Whether you need rough grinding for shaping or fine polishing for a flawless finish, this system delivers exceptional results. The motors are designed for durability and consistent performance, even under heavy workloads. - Rigid and Durable Construction

Built with the highest-quality materials, our machine features a robust base that ensures stability and minimizes vibrations during operation. This rigidity is critical for maintaining precision and achieving high-quality edges, especially for delicate applications like solar glass or furniture glass. - User-Friendly Design

The machine is designed with operators in mind. The rotating wheel mechanism not only simplifies maintenance but also reduces the physical effort required for wheel replacement. This user-centric approach enhances productivity and reduces labor costs. - Versatility for Multiple Applications

Our double edging line is highly adaptable, making it suitable for a wide range of glass types, including:

- Furniture Glass: Perfect for creating smooth, polished edges for tabletops, shelves, and decorative panels.

- Home Appliance Glass: Ideal for processing glass used in ovens, refrigerators, and other household appliances.

- Solar Glass: Ensures precision and durability for solar panel glass, where edge quality is critical for performance.

Technical Advantages

- High Efficiency: The dual-edger setup, combined with the straight turning table, ensures a seamless workflow, maximizing throughput and reducing processing time.

- Precision Engineering: Advanced control systems and high-quality components guarantee consistent edge quality, even for complex shapes and tight tolerances.

- Reduced Downtime: The 180-degree rotating wheel mechanism minimizes the time required for wheel replacement, keeping production lines running smoothly.

- Low Maintenance: The robust construction and high-quality materials ensure long-lasting performance with minimal maintenance requirements.

Why Choose Our Glass Pencil Double Edging Line?

- Enhanced Productivity: By reducing downtime and streamlining the grinding process, our line helps you achieve higher output without compromising quality.

- Superior Edge Quality: The combination of rough and fine polishing ensures a flawless finish, meeting the highest industry standards.

- Cost-Effective Operation: The durable design and low maintenance requirements translate to lower operating costs over the machine’s lifespan.

- Future-Proof Technology: With its innovative features and adaptability, our double edging line is designed to meet the evolving needs of the glass processing industry.

Applications in the Glass Industry

Our Glass Pencil Double Edging Line is a versatile solution for various sectors:

- Furniture Industry: Create elegant, polished edges for glass tables, cabinets, and decorative pieces.

- Home Appliance Manufacturing: Achieve precise edges for glass components used in appliances like ovens, microwaves, and refrigerators.

- Solar Panel Production: Ensure the highest quality edges for solar glass, where precision and durability are critical for performance and longevity.

Conclusion

Our Glass Pencil Double Edging Line represents the pinnacle of glass processing technology. With its innovative design, robust construction, and user-friendly features, it is the ideal choice for businesses looking to enhance their productivity, reduce costs, and deliver superior-quality glass products. Whether you’re processing furniture glass, home appliance glass, or solar glass, this line offers the precision, efficiency, and reliability you need to stay ahead in a competitive market.

Invest in our double edging line today and experience the future of glass processing technology. For more information or to request a demo, contact our team – we’re here to help you achieve excellence in glass fabrication.