Here’s a comprehensive and informative post introducing the necessary machines for home appliance glass processing factories. This post is designed to help you understand the essential equipment required for efficient and high-quality glass processing in the home appliance industry.

Essential Machines for Home Appliance Glass Processing Factories

The home appliance industry relies heavily on glass components for products like cook top, ovens, refrigerators, microwaves, washing machines, and more. To meet the demands of precision, efficiency, and quality, glass processing factories need a range of specialized machinery. Whether you’re setting up a new facility or upgrading your existing production line, here are the essential machines you’ll need to ensure smooth and efficient glass processing:

1. Glass Loading Robot

- Purpose: Automates the loading and unloading of glass sheets onto processing machines.

- Benefits:

- Reduces manual labor and increases safety.

- Ensures precise placement of glass sheets, minimizing errors and breakage.

- Improves production efficiency by streamlining the workflow.

- Applications: Loading or unloading glass sheets onto cutting tables, edging machines, or washing machines. There are different options for loaders, 3 axis or 5 axis.

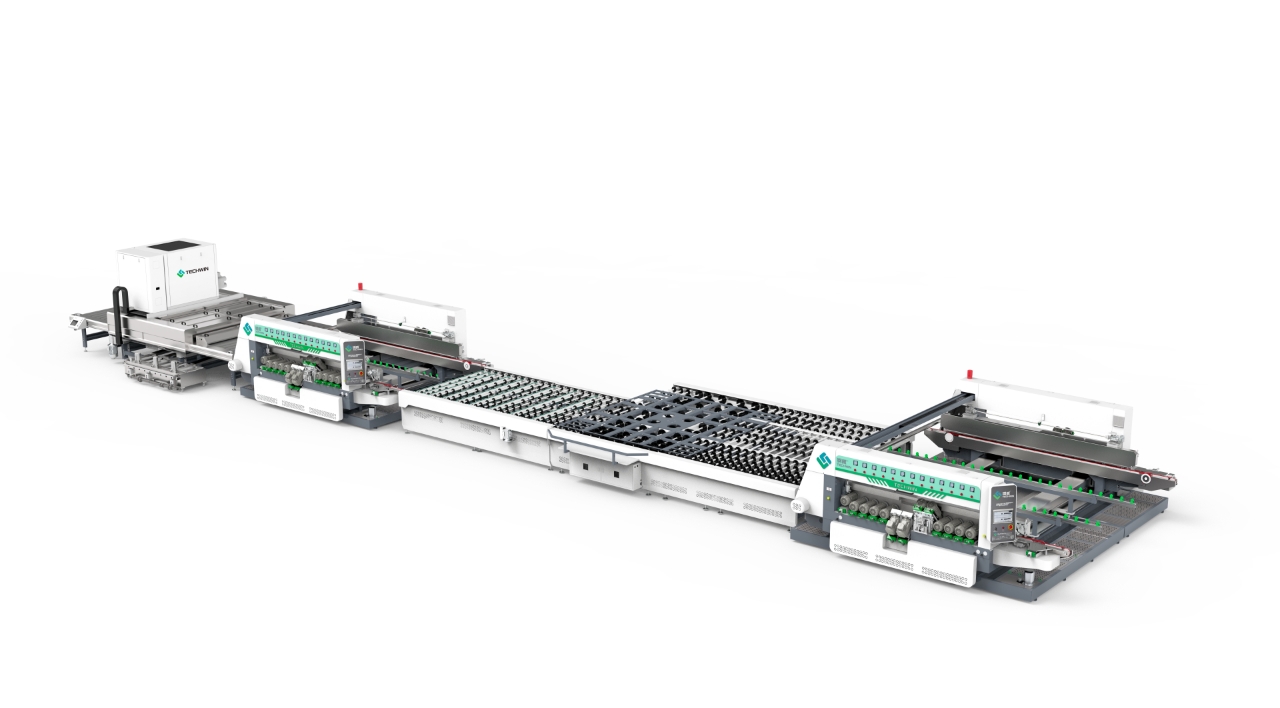

2. Glass Double Edging Machine

- Purpose: Grinds and polishes both edges of glass sheets simultaneously.

- Benefits:

- High-speed processing with up to 20 meters per minute.

- Equipped with 24 or 22 spindles for rough grinding, fine grinding, and polishing in a single pass.

- Ensures consistent and flawless edges, ideal for home appliance glass.

- Applications: Processing panels for cook tops, refrigerators, ovens, and microwaves. Round edges or straight edges are available.

3. Glass Corner Grinding Machine

- Purpose: Grinds and polishes the corners of glass sheets to achieve smooth, rounded edges.

- Benefits:

- Equipped with four spindles for fast and efficient online processing.

- CCD auto cameras ensure precision by correcting chamfering irregularities.

- Suitable for glass sheets of varying thicknesses.

- Applications: Creating polished corners for glass cook tops, refrigerators inner glass,electronic scale, and decorative pieces.

4. Glass Washing Machine

- Purpose: Cleans and dries glass sheets after processing to remove dust, debris, and residues.

- Benefits:

- Ensures spotless and streak-free glass surfaces.

- Reduces the risk of defects during further processing or assembly.

- Improves the overall quality of the final product.

- Applications: Cleaning glass in production line, after corner grinding or before screen printing.

5. Glass Drilling Machine

- Purpose: Drills precise holes in glass sheets for handles, hinges, or ventilation.

- Benefits:

- CNC-controlled for high accuracy and repeatability.

- Reduces the risk of cracking or chipping during drilling.

- Can handle multiple hole patterns and sizes.

- Applications: Drilling big holes for cook tops or range hoods.

6. Glass Screen Printing Line

- Purpose: Applies decorative patterns, logos, or functional coatings onto glass surfaces.

- Benefits:

- High precision and consistency in printing.

- Supports multiple colors and complex designs.

- Durable and scratch-resistant prints.

- Applications: Printing logos, indicators, or decorative patterns on glass panels for home appliances.

7. CNC Processing Machine

- Purpose: Performs precise cutting, shaping, and engraving of glass sheets.

- Benefits:

- High accuracy and flexibility for complex designs.

- Reduces material waste with optimized cutting paths.

- Ideal for custom or intricate glass components.

- Applications: Cutting and shaping glass for custom appliance designs or engraved decorative elements.

Why Invest in These Machines?

- Increased Efficiency: Automated machines like loading robots and CNC processors streamline production, reducing manual labor and downtime.

- Superior Quality: Precision equipment ensures flawless edges, smooth surfaces, and accurate drilling or printing.

- Cost Savings: Reduced material waste and lower labor costs lead to a higher return on investment.

- Versatility: These machines can handle a wide range of glass thicknesses, shapes, and designs, making them suitable for various home appliance applications.

- Competitive Edge: High-quality glass components enhance the overall appeal and functionality of home appliances, giving your products a competitive advantage in the market.

Conclusion

For home appliance glass processing factories, investing in the right machinery is essential to meet the industry’s demands for precision, efficiency, and quality. From glass loading robots and double edging machines to CNC processors and screen printing lines, each machine plays a critical role in ensuring smooth and efficient production.

By equipping your factory with these essential machines, you can enhance productivity, reduce costs, and deliver high-quality glass components that meet the highest standards. Whether you’re processing glass for ovens, refrigerators, or microwaves, these machines will help you stay competitive in the fast-paced home appliance industry.

If you’d like to add more details or tailor this post further, feel free to contact: franky@fstechwin.com!